A few years back I purchased a SiFive HiFive1 Rev B board to join in the RISC-V revolution. In this ...

A few years back I purchased a SiFive HiFive1 Rev B board to join in the RISC-V revolution. In this ...

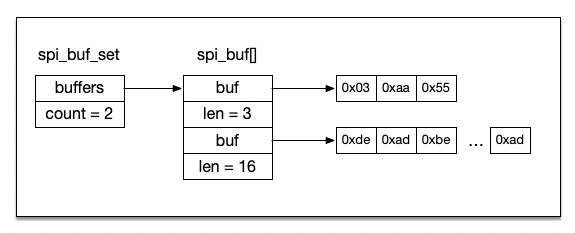

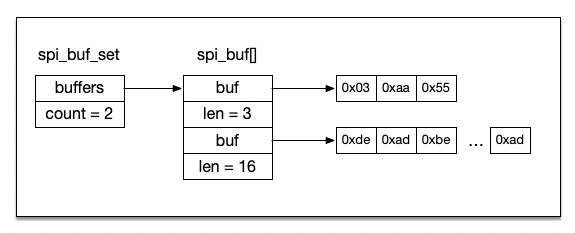

Hey kids! Today we’re going to take a look at the SiFive HiFive1 Rev B and Freedom Metal I2C API. ...

In our last post we looked at the GPIO pins of the SiFive HiFive1 Rev B board, and in this ...

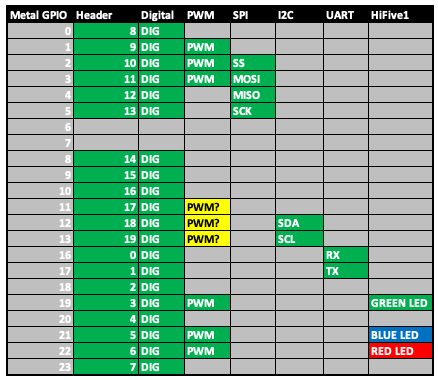

Let’s make use of the HiFive1 Rev B schematics to map out the GPIO controller device pins. Of particular interest ...

Today I’d like to introduce you to a new development board, the HiFive1 Rev B. Equipped with a RISC-V Freedom ...